1…ceny jedzenia są naprawdę wysokie

W pierwszej chwili, gdy obserwowałam restauracyjne witryny, w drodze z lotniskowego autobusu do hotelu, stwierdziłam, że z moją matematyką jest naprawdę mocno kiepsko. Duża pizza i dwa piwa za, w przeliczeniu na PLNY,80 zł wydała mi się omamem wzrokowym, wywołanym długą podróżą. Niestety, kolejne informacje z mijanych menu potwierdziły moje obawy – codzienne stołowanie się na argetyńskim mieście, może zrujnować Wasz budżet kompletnie. Dlatego, jeśli będziecie mieli możliwość nocowania w miejscu z dostępną kuchnią, wybierajcie tę opcję w ciemno. Zakupy w lokalnym dyskoncie wyjdą Wam mniej więcej jak w naszej poczciwej Biedronce, jedynie trzeba ciągnąć zapałki kto danego dnia pełni dyżur kuchcika.

Alternatywą dla restauracji czy popularnych perrillas, czyli knajp serwujących wołowinę z grilla, mogą być uliczne stoiska z rożnymi przekąskami. Na uwagę zasługują na pewno budy oferujące empanadas, czyli pierożki nadziane różnymi farszami, które dla obywateli kraju znad Wisły przywodzą na myśl dom i swojskie smaki, jeno w nowej odsłonie. Króluje wypełnienie mięsne, ale znajdą się też warzywne czy serowe opcje. W tym miejscu muszę jednak zmartwić wege-turystów. Otóż o ile np. w Brazylii mieliśmy wiele możliwości zaspokojenia głodu, chociażby podanymi na gazylion sposobów owocami, o tyle w krainie stejków, jaką jest Argentyna, bezmięsne posilanie się do najłatwiejszych zadań nie należy. (i najsmaczniejszych, jak zaobserwowaliśmy pomysły na niektóre “dania”).Więc miejcie to na względzie.

2. cambio, ale nie dolor, lecz dinero

Przed wyjazdem wyczytaliśmy, że najbardziej opłaca się wymieniać pieniądze na ulicy. Jako dzieci wychowane u schyłku komuny słyszeliśmy co nieco o cinkciarzach, jednakże uznaliśmy, że to totalna prehistoria i nastawiliśmy się na klasyczne odwiedziny w bankach. I tu, jak się okazało, ponieśliśmy sromotną klęskę w dziedzinie ekonomii. Otóż ulice Buenos Aires, zwłaszcza te mocno turystyczne, pełne są ludzi bez krępacji zaczepiających przechodniów słowami “cambio, cambio”, oznaczające nic innego jak tylko “wymienię,wymienię”. Nie należy się ich bać, odganiać parasolką, ani węszyć szwindla. Ci przedsiębiorczy Argentyńczycy mają swoje rewiry, zazwyczaj stoją dzień dnia w tym samym miejscu, więc w razie czego w każdej chwili można do nich wrócić z reklamacją. Doświadczenie dobitnie pokazało, że powinniśmy byli korzystać z ich niezarejestrowanych w KRS usług. W marcu 2015 r. absolutnie nie opłacało nam się chodzić do oficjalnych placówek i gdybyśmy tylko mieli przy sobie więcej amerykańskich dolochów, nie musielibyśmy tak zaciskać pasa. No cóż. Jak to mawiają najstarsi górale – ten się nie myli, kto nic nie robi.

3. stejki są naprawdę obłędne

Tak, wiem. Jako osobie niejedzącej mięsa takie stwierdzenie naprawdę nie przystoi. Cóż mogę począć- naszego bloga czytają ludzie różnych wyznań kulinarnych i jestem zobligowana do zachowania chociaż minimalnej dozy obiektywizmu (zwłaszcza, że wypowiadam się również w imieniu Sebastiana). A prowadzi on do jednoznacznej konkluzji – jeśli nie jadłeś grillowanej wołowiny w Argentynie, nie jadłeś wołowiny wcale. Jest ona dostępna absolutnie wszędzie, nie tylko w perrillas – w zasadzie każda knajpa ma w swojej ofercie to szlachetne mięso, przyrządzane na różne sposoby. Przetestowaliśmy na własnej skórze i zarówno te podane w wykwintnych restauracjach, jak i w podrzędnych barach, są niebem w gębie. Ze względu więc na fakt, iż tambylcy wiedzą, że turyści ostrzą sobie kły na średnio lub dobrze wysmażone kawały chabaniny, to windują jej ceny czasami niebotycznie, dlatego nie ma co się pchać na niewiadomo jakie salony (aczkolwiek bez bicia przyznam, że dla mięsożerców to danie jest warte każdych absolutnie pieniędzy). Po prostu wchodźcie do pierwszego z brzegu miejsca, z podwojów którego dolatuje obłędny zapach. My jedliśmy najlepsze steki na totalnym odludziu, w części, którą wszyscy napotkani w czasie spaceru mieszkańcy, odradzali nam do odwiedzin. A i tak było obłędnie (tak smakowo, jak i ze względu na atmosferę).

4. dzielnica dzielnicy nierówna

Buenos to miasto kontrastów. Niektóre jego części są wymuskanymi perełkami, dzięki którym stolica Argentyny nazywana jest Paryżem Ameryki Południowej (aczkolwiek nam kojarzyła się bardziej z Madrytem, kwestia percepcji). Inne zaś to dzielnice “spod ciemnej gwiazdy”, do których rozsądni ludzie się nie zapuszczają. My w czasie wakacji wyjmujemy zawodowe kije z tyłków i pozwalamy sobie niejednokrotnie na nonszalancję (przez niektórych nazywaną głupotą), która sprowadza się m.in. do spacerów szlakami oddalonymi od głównych turystycznych atrakcji, dlatego miasto zwiedziliśmy dość dogłębnie. Wyluzowaliśmy się tym bardziej, że do Buenos trafiliśmy prosto z Rio de Janeiro, które naprawdę nie należy do najbezpieczniejszych miejsc na globie, więc gdy mogliśmy pozbyć się brazylijskiej spiny, lataliśmy jak wścieknięci, korzystając z wolności i swobody.

Czy było to mądre? Nie wiem. Z części miejsc rzeczywiście wyzierała spora bieda, która często może prowadzić do przemocy lub agresji. Ponieważ jednak nie epatowaliśmy bogactwem i swego rodzaju pychą, typową czasem dla niektórych przedstawicieli pierwszego świata, plus dodatkowo decydowaliśmy się na posiłki w lokalnych spelunach, nic nam się absolutnie nie stało. Ba, jednego z kucharzy knajpy położonej niedaleko stadionu zwanego przez tambylców La Bomboniera mamy nawet na fejsie (do tej pory przysyła nam życzenia świąteczne). Wszystko więc się da, byle względnie z głową i sensownym wypośrodkowaniem.

Północ i zachód to tzw. villas miserias, czyli dzielnice zajmowane przez ludzi uboższych. Piękne centrum, to z kolei miejsce skupiające najważniejsze historyczne obiekty, otoczone przez luksusowe osiedla i wymuskane parki. Turyści zazwyczaj zwiedzają Palermo, Recoletę, Retiro. Nas zachwyciło najbardziej San Telmo, (dlaczego- o tym nieco dalej) oraz Boca (o której w kolejnym poście).

Generalnie w Buenos każdy znajdzie coś dla siebie. Z jednej strony pokojówki i dzieci w mundurkach, z drugiej zaś knajpy, w których przyprawy przesypane są do starych butelek po Coca-coli. Istny miszmasz.Pamiętajcie jednak, że to miasto rozciąga się na powierzchni 200 kilometrów kwadratowych, co powoduje, że warto zaopatrzyć się w wygodne obuwie, które pozwoli nam zwiedzać je w jak najbardziej komfortowy sposób.(o jego ogromnie świadczy m.in. fakt, że mimo iż jest podobno największym skupiskiem Polonii w całej Ameryce Południowej to w czasie naszego pobytu nie natrafiliśmy na żadnego rodaka, co nam się w zasadzie w czasie podróży wszelakich nigdy nie zdarza).

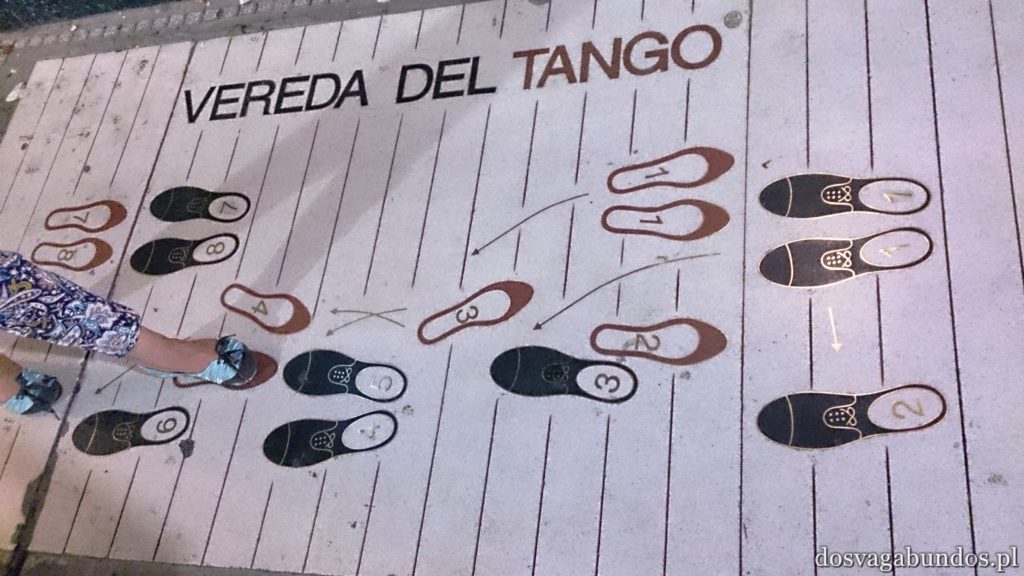

5. tango tańczyć każdy może, trochę lepiej lub trochę gorzej

Jako osoba, która kocha taniec nad życie, zawsze namawiam wszystkich, aby przełamali swoje opory psychiczne i zaczęli regularnie wpadać na jakieś jego treningi. Niestety, dla większości osób bariera w głowie, dotycząca braku koordynacji ruchowej, ucha Van Gogha i kiepskiej pamięci choreograficznej, jest nie do przekroczenia. Jeśli tak jest i w Waszym przypadku, jednak w skrytości ducha marzycie, aby dać się ponieść się muzyce, w kilka sekund wyrzucicie z głowy wewnętrznego kaprala-wstydziocha i poddacie tańcu na ulicach Buenos Aires właśnie. Tam wije się każdy. Młody, stary, gruby, brzydki, piękne kobiety i te, do oglądania których potrzeba nieco więcej wina.

Oczywiście absolutnie i niepodważalnie dominuje tango, pochodzące z Buenos właśnie, i wszelkie jego odmiany typu vals, nuevo czy milonga. Pokazów jest mnóstwo – od wyreżyserowanych pod turystów show, po akcje zawiązywane całkowicie ad hoc, które ze względu na swoja spontaniczność są najbardziej szczere, porywające i zachęcające do dołączenia się.

Żeby złapać na nie totalnego bakcyla najlepiej przejść się wieczorem na jakąś klimatyczną uliczkę, dodać animuszu pysznym winem i po 2h wywijać pląsy na oczach nastawionego na świetną zabawę tłumu (ja próbowałam również w ciągu dnia, aczkolwiek wieczór dodaje tajemniczości, więc ci co mniej pewni siebie będą się czuli swobodniej). A przynajmniej dać ponieść doświadczonemu partnerowi, który poprowadzi Was niczym Rafał Maserak w Tańcu z Gwiazdami. Mnie porwał w obroty jakiś starszy Pan, gdy próbowałam nad ranem odtworzyć podstawowe kroki, rozrysowane na chodniku jednej z ulic. CUDO.

6. dulce de leche potwierdza fakt, że krówki na całym świecie smakują wybornie

Tym razem nie chodzi o pochodzące z ich mięsa steki (hmmm, natężenie sucharów zaczyna być niepokojące, muszę zacząć się hamować), lecz o najpopularniejszą argentyńską słodkość, do złudzenia przypominającą naszą swojską ciągutkę. “Słodycz z mleka” to po prostu kajmak, serwowany w rożnych stanach skupienia, począwszy od mocno płynnych, po kruche cukieraski. Nawet znane we wszystkich hiszpańskojęzycznych krajach churros, czyli tłuste rurki zrobione z ciasta takiego jak na nasze pączki, bywają tam wypełnione nie tradycyjnie czekoladą a gęstym dulche de leche właśnie. Warto więc spróbować, żeby utwierdzić się w przekonaniu, że co jak co, ale słodycze zdecydowanie są ponad podziałami.

7. pokochasz yerba mate

Zauważyłam, że yerba mate, czyli napar z wysuszonych i zmielonych liści ostrokrzewu paragwajskiego, jest coraz bardziej popularna w Polsce. Jednakże gdzie nam do Argentyńczyków, którzy w zasadzie wszędzie popylają z pękatymi naczynkami zwanymi mate, (tudzież ze zwykłymi termosami lub kubkami termicznymi), z których sączą swoiście pachnący płyn przez drewniane lub srebrne słomki określane mianem bombilli. Ta osobliwa herbatka jest bardzo popularnym napojem w krajach Ameryki Południowej, aczkolwiek ze względu na jej właściwości zdrowotne powinna być hołubiona na całym świecie. Jej picie pomaga obniżyć poziom cholesterolu we krwi, stymuluje układ nerwowy, korzystnie wpływa na układ krążenia. No a przede wszystkim yerba, przez Indian nazywana caá, stanowi zdrową alternatywę dla kawy.

Tradycyjnie pija się ją w naczynkach przypominających bombki choinkowe, które mogą być wykonane z tykwy, czyli rośliny tropikalnej z rodziny dyniowatych, ceramiki lub drewna np. palo santo. My kupiliśmy sobie do domu ten ostatni rodzaj, a do tego uliczny sprzedawca wyrzeźbił dla nas specjalnie dedykację – polecamy, świetna, funkcjonalna pamiątka (a nie jakaś tam durnostojka). Yerbę można również pić z tzw. guampy, czyli naczynia wykonanego z rogu bawolego albo krowiej racicy, aczkolwiek my zdecydowanie bardziej jesteśmy za tym pierwszym rozwiązaniem. Natomiast ze względu na fakt, że jest ona mocno fusiasta, zaciąga się ją przez specjalne rurki, zakończone sitkiem, zrobione z alpaki, srebra czy stali nierdzewnej.

Po powrocie do kraju regularnie pijaliśmy to cudo, jednak z biegiem czasu okazaliśmy się nań zbyt leniwi. To zaparzanie w specjalnej temperaturze, odczekiwanie, suszenie, pozbywanie fusów, cały bądź co bądź ciekawy, ale relatywnie długi rytuał okazał się za wolny na nasze tempo życia. Co nie zmienia faktu, że w weekendy, gdy nigdzie się nie spieszymy i możemy po śniadaniu zalec z psem na kanapie, zaparzamy sobie yerbę w oryginalnych matach i wracamy głową do wakacji 2015.

8. pokonasz jedną z najszerszych ulic świata

Naprawdę robi wrażenie. Znajdująca się w samym centrum Aleja jest jedną z najszerszych (w jednym miejscu ma aż 140 m!) ulic na świecie (punkty za przeprowadzenie przez nią staruszki mnoży się przez 4). Biegnąca od Plaza Constitución do Avenida Libertador aleja posiada, bagatela, 8 pasów ruchu w każdym kierunku, więc przebiegać przez nią w niedozwolonym miejscu raczej nie należy. Jej nazwa, czyli Avenida 9 Julio, upamiętnia dzień uzyskania przez Argentynę niepodległości w 1816r. Na szczęście wyposażona jest w sprawną sygnalizację świetlną, więc przejście przez nią nie stanowi jakiegoś herkulesowego wysiłku.

W miejscu, w którym krzyżuje się ona z Aleją Corrientes, czyli na Placu Republiki, dumnie pręży się El Obelisco, który z kolei został wzniesiony w 400 rocznicę osiedlenia się pierwszych hiszpańskich osadników w Río de la Pata, czyli nieco ponad 80 lat temu. Jest dość wysoki, gdyż mierzy prawie 70 metrów, trudno go więc przeoczyć. Dlatego jeśli zamajaczy Wam na horyzoncie, to znaczy, że macie iść w jego stronę i w ten łatwy sposób dotrzecie do centrum Avenida 9 Julio. Na marginesie warto dodać, że fota pod obeliskiem tak czy siak musi być, ponieważ monument jest podobno główną wizytówka miasta, pod którą spotykają się ludzie w celach artystycznych, happeningowych czy kibolskich. A na drugim marginesie, to przy Avenida 9 de Julio znajduje się jeden z największych teatrów operowych na świecie, Teatr Kolumba (Teatro Colón), mogący pomieścić nawet 3500 widzów.

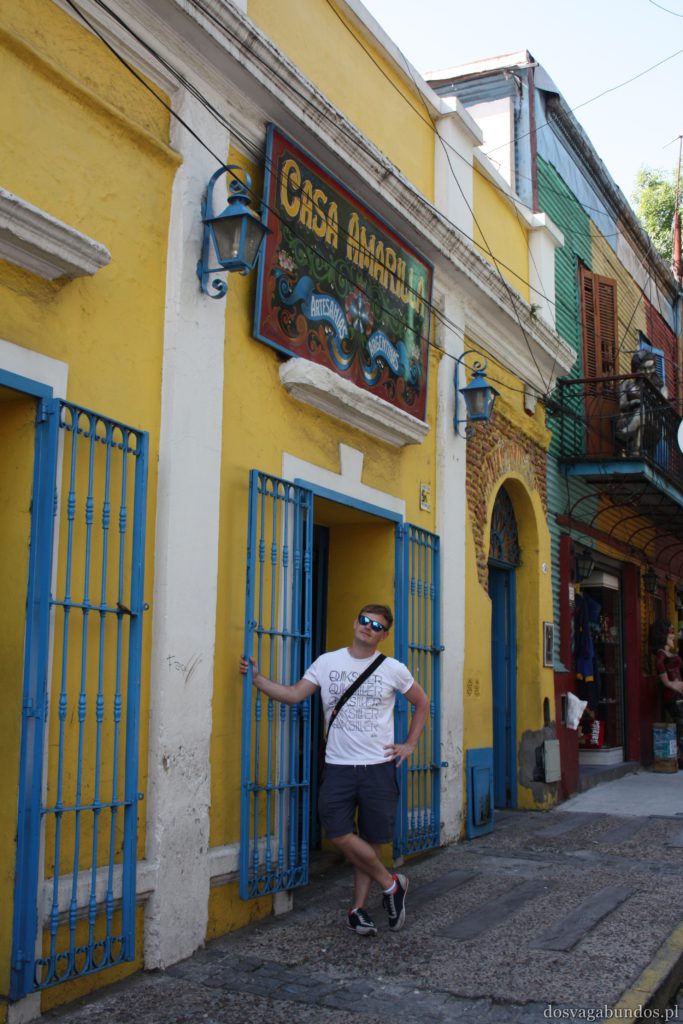

9. kolorowe San Telmo gwarantuje zastrzyk pozytywnych emocji

Ta najstarsza dzielnica Buenos jest naprawdę magiczna. Zwłaszcza po zmroku. Ale i w ciągu dnia nie pozwala się nudzić. Jest pełna rzemieślników, artystów, tancerzy, dających koncerty na żywo muzyków, sprzedawców dóbr wszelakich. Upstrzona sklepikami, klimatycznymi kawiarniami, klubami, galeriami. Jest gwarno, kolorowo, ale nie w irytująco męczący sposób. Człowiek wtapia się w atmosferę tego miejsca i już nie chce z niej wydostać. Tam się rozmawia, ogląda, chłonie każda komórką ciała wszystko, co Argentyna ma do zaoferowania. Ludzie tańczą, śmieją się, żyją pełnią życia. Jest naturalnie, bezpretensjonalnie, różnorodnie a jednocześnie spójnie. Nie ma miejsca na snobizm, drogie samochody, selekcje. Jest za to rozrywka przez duże R. Czyli to, co tygryski lubią najbardziej.

10. Maradona jest żywą legendą

Najpopularniejszym sportem w Argentynie jest oczywiście piłka nożna. Nie dziwota więc, że uważany za jednego z najlepszych graczy w historii tego sportu, a także wybrany najlepszym zawodnikiem XX wieku Diego Maradona obecny jest co krok na ulicach argentyńskiej stolicy. Chociaż urodził się w zupełnie innym mieście, część jego kariery związana jest z ponad stuletnim Club Atlético Boca Juniors, którego stadion można podziwiać w czasie zwiedzania portowej dzielnicy Buenos Aires – La Boca (swoją drogą bardzo ciekawe miejsce, opisowi którego poświęcimy nieco więcej uwagi przy kolejnym poście). To taki ichniejszy bohater, jak u nas Małysz czy obecnie może Lewandowski (aczkolwiek murali z Lewym jeszcze nie widziałam). My raczej footbalmaniakami nie jesteśmy, ale po kolejkach przed nazywanym przez lokalsów “Bombonierką” stadionem mogliśmy wywnioskować, że dla niektórych to prawdziwa mekka.

Lecąc na Kubę miejcie świadomość, że… | Dosvagabundos.pl

[…] wystarczy jednak jak np. w Argentynie wyhaczyć któregoś z wielu cinkciarzy (pisaliśmy o tym w jednym z tekstów). Tu wszystko jest ściśle sterowane przez partię i tak zorganizowane, żeby nikomu […]

Aluminum scrap export/import regulations Sell aluminum scrap Aluminum cable

Aluminium scrap supply and demand Scrap aluminium business opportunities Aluminum waste management

Industrial copper reuse Copper scrap distribution Copper scrap recycling

Copper wire bar scrap procurement Copper scrap community outreach Copper scrap recycling procedures

Copper heat exchanger recycling Scrap Copper wire stripping machine Copper scrap extrusion

Scrap copper sales Copper scrap material handling Industrial copper recovery

Scrap metal removal Ferrous waste collection Iron scrap recovery plant

Ferrous material compaction services, Scrap iron collection, Scrap metal environmental impact

Metal recycling industry certifications Aluminium alloy reclamation Aluminium scrap resource recovery

Scrap metal repurposing strategies, Aluminum cable scrap exporters, Metal scrap reprocessing

Scrap metal disposal Aluminum scrap dealers Aluminium scrap value maximization

Bronze scrap recycling, Recycling regulations for aluminum cable scrap, Scrap metal refurbishment

Sustainable metal recovery practices Aluminum scrap trading market Aluminium recovery

Scrap metal waste disposal, Aluminum cable waste, Scrap metal warehousing

Metal reclaiming operations Aluminium tool recycling Aluminium recycling market expansion

Scrap metal recovery and processing, Melting aluminum cable, Scrap metal reclamation site

Metal waste salvage Aluminum coil scrap Aluminium scrap collection services

Metal recovery and reclamation services, Aluminum cable recycling center, Metal reutilization

Export procedures for Copper scrap Copper scrap sourcing network Copper scrap purity standards

Metal market analysis services, Copper chromate recycling, Metal reclamation solutions

Copper scrap packaging Copper wire can conduct electricity efficiently and safely, but it is not suitable to use as a fuse wire because of its low melting point. A fuse wire is designed to break and disconnect the circuit in case of an overcurrent or short circuit, which can damage devices, cause electrical fires, or pose a risk to people’s safety. When too much current passes through a fuse wire, it heats up and melts, interrupting the flow of electricity. The fuse wire must be able to handle the normal electrical load without melting, but it should melt quickly if an abnormal current surge occurs. Copper wire has a melting point of 1085В°C, which is too high for most applications. In contrast, a typical fuse wire made of materials like tin, lead, or alloys has a melting point between 100В°C and 250В°C, depending on the current rating and environment. Using a copper wire as a fuse wire could cause several problems. Firstly, it may not break quickly enough to protect the circuit, device, or user from the effects of a fault. Secondly, it may not produce a visible indication that the fuse has blown, making it difficult to identify and troubleshoot the fault. Thirdly, it may potentially cause a fire if the copper wire becomes heated to its melting point. Therefore, it is critical to use appropriate fuse wire material that is safety-approved, correctly rated, and installed correctly according to standards and regulations to ensure reliable protection and prevent electrical hazards Scrap metal profit margins Integrated copper recycling Copper scrap prices per pound Scrap copper recycling process Recycling regulations for Copper scrap Scrap metal recovery industry

Scrap copper processing Copper metal is widely used as a conductor of electricity due to its excellent electrical conductivity and other beneficial properties that make it an ideal material for electrical wiring. There are several reasons why copper is chosen over other metals for electrical wiring: 1. Excellent electrical conductivity: Copper has a very high electrical conductivity, which means that it can easily transfer electrical energy from one place to another. This allows for efficient transmission of electrical power over long distances, with minimum loss of energy due to resistance. 2. Low resistance: Copper has low electrical resistance, which means that it does not hinder the flow of electricity, and electrical energy can pass through it with ease. This low resistance ensures that a high percentage of the electrical energy is transmitted without being lost as heat. 3. Ductility and flexibility: Copper is a malleable and ductile metal, which means that it can easily be bent and shaped without breaking. This makes it perfect for use in tight spaces and situations where wires need to be routed in complex patterns. 4. Corrosion resistance: Copper is highly resistant to corrosion, which means that it can resist environmental factors such as humidity, water, and temperature variation for a long time without losing its conductivity. 5. Availability and Cost-effectiveness: Copper is widely available, and its cost is relatively cheap as compared to other metals of similar quality. This ensures that it is not only the best material for electrical wiring but also the most cost-effective solution. In conclusion, copper is an excellent choice for electrical wiring because of its excellent electrical conductivity, low resistance, ductility, corrosion resistance, availability, and cost-effectiveness. These properties make it the preferred material for electrical wiring in almost all applications, ranging from residential wiring to heavy-duty industrial applications Metal waste reconditioning Clean copper recycling Copper scrap market differentiation Secondary copper market Copper alloy melting Scrap metal regeneration

Scrap metal appraisal Metal recycling and recovery services Iron sorting

Ferrous scrap reclaiming, Iron scrap yard management, Metal salvaging

Metal scrap market research Ferrous material green initiatives Iron scraps reprocessing

Ferrous material process improvement, Iron scrap recycling industry, Metal waste recovery and recycling

Metal reprocessing Ferrous material safety procedures Iron waste collection points

Ferrous material auditing, Iron waste reclamation, Scrap metal recycling depot

Metal scrap export regulations Ferrous waste recycling programs Iron reprocessing and reclaiming

Ferrous metal inventory management, Iron recycling facility, Metal recycling methodologies

Metal recycling Ferrous material recycling customer service Iron waste reclamation facility

Ferrous material social responsibility, Iron scrap pricing, Metal waste refabrication