Chociaż wpis znajduje się w sekcji “Jednodniowe wypady z Warszawy”, tak naprawdę do skansenu, będącego częścią Muzuem Rolnictwa im. ks. Kluka w Ciechanowcu, można w prosty i szybki sposób dojechać również z Białegostoku czy też Białowieży. Kompleks ten, obejmujący kilkadziesiąt zabytkowych obiektów, znajduje się bowiem na pograniczu Mazowsza i Podlasia.

Sama trasa prowadząca do Muzuem jest już naprawdę ciekawym doświadczeniem – my stawaliśmy po drodze jakieś bilion razy, żeby zrobić fajne zdjęcia. I chociaż była wtedy jeszcze zima, jak widać na załączonych obrazkach nie tylko kalendarzowa, udało nam się zaczerpnąć tyle słońca, że momentami chodziliśmy w samych t-shirtach.

Skąd w ogóle pomysł na taką wyprawę? Otóż jak wiadomo mamy pandemię i spędzanie czasu na świezym powietrzu stało się nie tylko jedyną sensowną opcją, koniecznością, ale i nową normą, którą zdecydowanie popieramy. Ze spacerów będziemy się mogli chyba niedługo habilitować. I co istotne – wcale nam to nie przeszkadza (aczkolwiek – żeby była jasność- za wolnością w postaci możliwości spotkań z przyjaciółmi w knajpach, kinie czy na imprezie, tęsknimy niewymownie :().

Anyways. Przestrzeń całego Muzeum, położonego na terenie XIXwiecznego zespołu pałacowo-parkowego, jest naprawdę spora. Większość czasu zwiedzający spędzają na zewnątrz, jeśli zaś wchodzą do środka to z zachowaniem wszelkich zasad bezpieczeństwa sanitarnego.

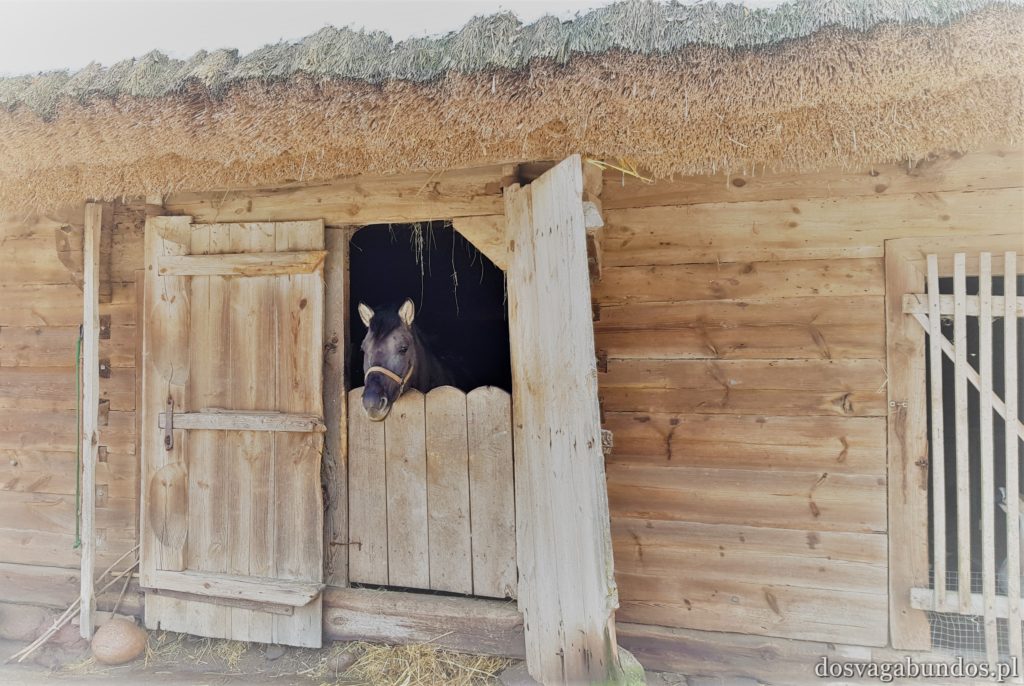

Podczas wizyty można podziwiać m.in. klasycystyczny pałac, wozownię czy też młyn wodny, a także prawie 50 zabytkowych obiektów architektury drewnianej (przeniesionych ze wsi położonych na pograniczu województwa mazowieckiego i podlaskiego).

Co istotne, spacerując między zróżnicowanymi obiektami można zajrzeć do ich wnętrz i zapoznać się nie tylko z ekspozycjami stałymi (np. obejrzeć kolekcję ponad 2200 pisanek z całego świata czy też zachwycić wnętrzami pałacowymi) bądź czasowymi, lecz także wziąć udział w jednej z cyklicznych imprez (w czasach, w których będzie to pandemicznie możliwe, chlip) czy wręcz spędzić noc w jednej z zabytkowych chat.

Miejscem wartym uwagi, szczególnie na wiosnę, gdy wszystko kwitnie, słońce rozpieszcza i spacerowanie jest ekstremalną wręcz przyjmenością, jest ogród roślin zdatnych do zażycia lekarskiego. Jak można przeczytać na stronie muzeum “(…) doboru roślin dokonano na podstawie XVIII wiecznego rejestru – „Dykcjonarza roślinnego” ks. Krzysztofa Kluka. Każda roślina została opatrzona tabliczką informacyjną, zwierającą dane: nazwę łacińską, nazwę polską oraz przeznaczenie w lecznictwie”. Naprawdę fajnie to wygląda.

Jeśli natomiast znudzi Wam się promenowanie między zabytkami i dostarczanie sobie wiedzy na temat naszych przodków, możecie usiąść w altanie nad stawem i najnormalniej w świecie pochillować na świeżym powietrzu. Mistrzostwo świata.

Koszt takiego pełnego atrakcji dnia jest w zasadzie żaden- bilet normalny to zaledwie 14zł. Aktualny cennik, jak również informacje na temat aktualności najlepiej oczywiście sprawdzać na stronie muzuem – zawiera ona zresztą mnóstwo ciekawych informacji, których z oczywistych względów w tym krótkim wpisie nie przytoczyliśmy. https://www.muzeumrolnictwa.pl/

Zresztą przekonajcie się sami. Naprawdę warto.

Aluminum scrap metal prices Aluminium recycling industry growth Aluminium scrap containing

Copper scrap grading system Scrap copper annealing Environmental certifications for copper recycling

Copper scrap sampling Scrap Copper reuse Copper scrap chemical treatment

Copper reclamation services Industrial copper recycling techniques Copper scrap material composition

Metal recycling and salvaging Scrap aluminium value Scrap aluminium community engagement

Scrap metal purity standards, Aluminum cable recycling guidelines, Industrial metal recovery

Salvage metal recycling Scrap aluminum industry Scrap aluminium cleanliness

Scrap metal recovery and repurposing, Buying aluminum cable, Sustainable metal recycling initiatives

Scrap metal processing Aluminium recycling industry compliance Scrap aluminium transportation

Scrap metal refinishing, Recycle aluminum cables, Scrap metal repur

Scrap metal legal compliance Aluminium scrap environmental impact Aluminium recycling energy efficiency

Scrap metal reprocessing solutions, Aluminum cable scrap grades, Scrap metal recovery management

Scrap metal cutting Scrap aluminium industry standards Scrap aluminium life cycle analysis

Metal salvage yard operations, Aluminum cable recycling companies, Scrap metal community engagement

Scrap metal processing yard Scrap aluminum Recycling facilities for aluminum scrap

Scrap metal reutilization yard, Aluminum cable scrap recycling rates, Metal reclaiming yard collection

Copper scrap inspection Copper scrap recycling infrastructure Copper scrap exporters

Metal waste melting, Industrial Copper scrap, Scrap metal reclamation industry

Copper recycling certifications Mining has been a vital part of human history for over 70 centuries. From the stone tools used by prehistoric miners to the advanced technologies used today, mining has played a crucial role in shaping our world. Early mining was primarily focused on obtaining valuable materials such as flint, obsidian, and gold. During the Bronze Age, copper, tin, and iron became important materials for tools and weapons. The ancient Egyptians mined for gold and other precious metals, while the Romans focused on mining lead and silver. The rise of the Industrial Revolution in the 18th century brought about significant advances in mining technology, leading to larger scale operations and increased production. Coal mining in particular became a major industry, fueling the growth of cities and powering the steam engines that drove the economy. As mining continued to evolve, so did the challenges it presented. Advances in technology led to safer and more efficient methods of extraction, but also resulted in environmental concerns and labor disputes. Today, mining plays a critical role in supplying raw materials for a wide range of industries, from construction to electronics. The industry has also embraced sustainable practices, striving to minimize its impact on the environment and promote responsible resource management. Exploring 70 centuries of mining history offers a glimpse into the ingenuity, perseverance, and innovation that have been integral to human progress Metal scrap reclamation process Copper rod scrap buying Scrap Copper dealers Copper powder recycling Copper scrap classification Metal recovery and reclamation

Copper billet production Copper wire can conduct electricity efficiently and safely, but it is not suitable to use as a fuse wire because of its low melting point. A fuse wire is designed to break and disconnect the circuit in case of an overcurrent or short circuit, which can damage devices, cause electrical fires, or pose a risk to people’s safety. When too much current passes through a fuse wire, it heats up and melts, interrupting the flow of electricity. The fuse wire must be able to handle the normal electrical load without melting, but it should melt quickly if an abnormal current surge occurs. Copper wire has a melting point of 1085В°C, which is too high for most applications. In contrast, a typical fuse wire made of materials like tin, lead, or alloys has a melting point between 100В°C and 250В°C, depending on the current rating and environment. Using a copper wire as a fuse wire could cause several problems. Firstly, it may not break quickly enough to protect the circuit, device, or user from the effects of a fault. Secondly, it may not produce a visible indication that the fuse has blown, making it difficult to identify and troubleshoot the fault. Thirdly, it may potentially cause a fire if the copper wire becomes heated to its melting point. Therefore, it is critical to use appropriate fuse wire material that is safety-approved, correctly rated, and installed correctly according to standards and regulations to ensure reliable protection and prevent electrical hazards Metal reusing facility Copper scrap exporters Copper hydroxide recycling Copper scrap industry associations Copper recycling center Scrap metal recycling services

Metal scrap buyers Scrap metal recovery industry Iron scrap processing plant

Ferrous material recycling industry collaboration, Iron scrap reclamation facility, Metal waste management

Metal waste stream management Ferrous material emissions control Iron reclaiming yard collection

Ferrous material recycling cost-effective solutions, Iron waste processing, Scrap metal collection and recycling

Eco-friendly metal recovery Ferrous material recycling events Iron recycling

Ferrous metal demand, Iron waste drop-off, Scrap metal safety protocols

Scrap metal depots Ferrous material environmental compliance Iron recyclables processing

Ferrous metal recycling and reclamation facility, Iron redistribution, Scrap metal recovery and trading

Metal scrap facility Ferrous material dismantling Iron scrap reclamation yard

Ferrous material material restoration, Iron scrap transportation, Metal waste reclaiming solutions